How it works

By installing RFID tags in or around the inlet of the fuel tanks of all owned vehicles, equipment, and machinery, all dispensing operations are strictly restricted to RFID tag holders registered in the system. The fuel dispenser will not pump the fuel until a certain procedure is followed. This might vary from one application to another but things like driver ID, fuel issuer ID, odometer reading, and project or delivery note number are standard.

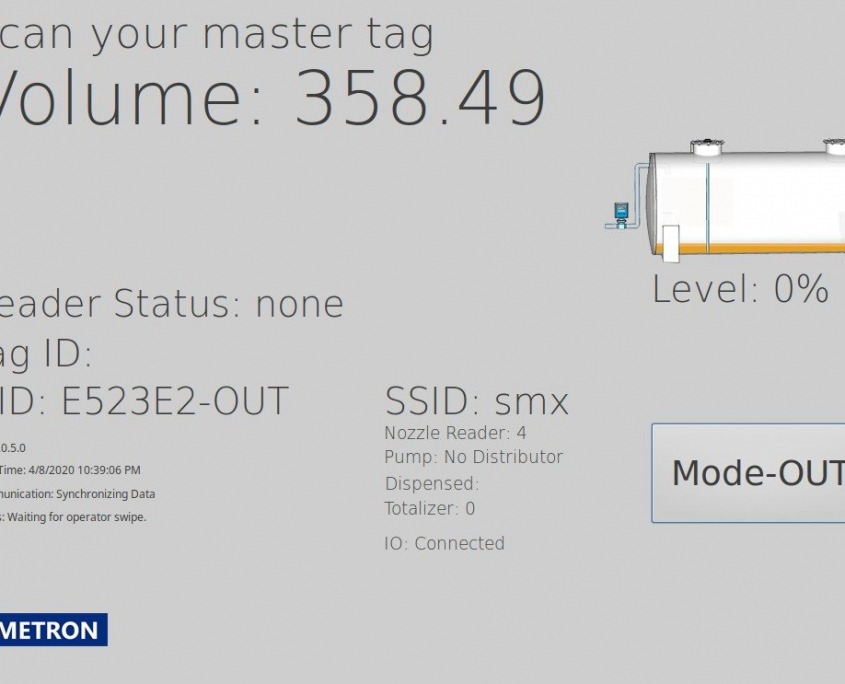

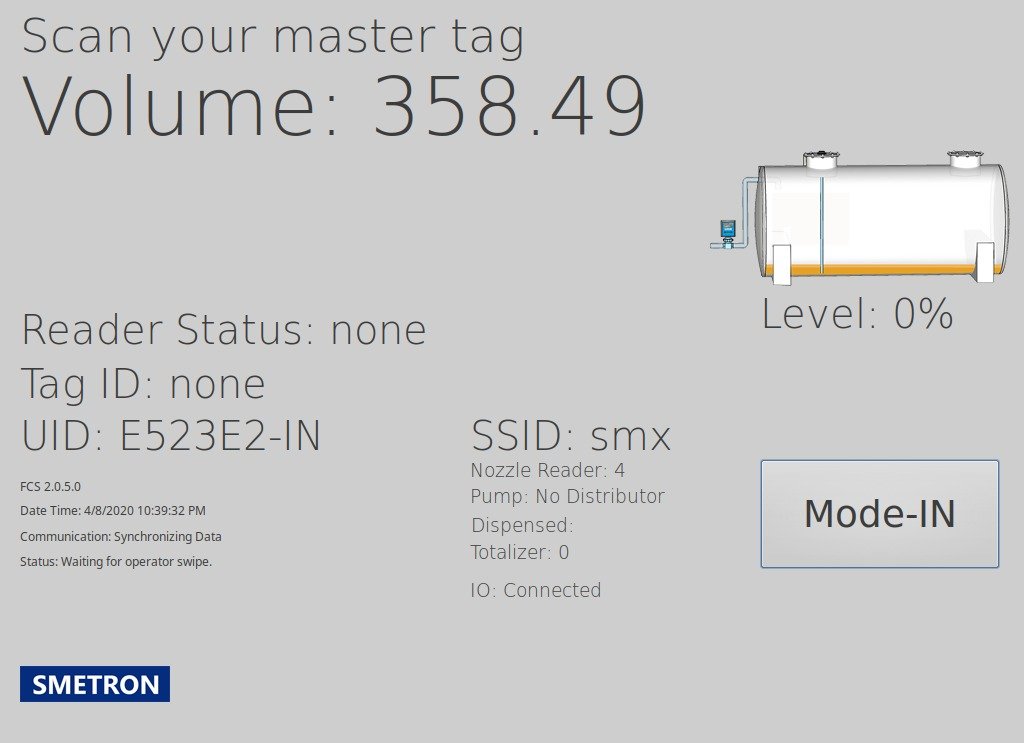

Once the vehicle, the driver, and the fuel issuer are authenticated and the odometer reading is captured, Fuel-EYE activates the pump. The flow meter counts and volumes are digitally displayed on the Gatex totalizer.

All this data is transmitted to the Gatex cloud servers for record-keeping and reporting purposes. A replica of the transactions is stored in the internal database of the fuel controller forever.

Each transaction is uploaded to the server within a few seconds after the fueling ends. If the network is not accessible, the transactions are kept in the internal memory for further upload attempts once the network is available. There is no limit on the number of stored transactions in the internal database of the controllers.

The system positions all the fuel management personnel on top of things by providing them the vital data relevant to each role player in the form of detailed transactions logs instantly as they occur and remote control mechanisms accessible on the web via connected devices, with user credentials, access levels, rights and privileges assigned to each role player in the company.

This could only have been possible with full automation of all fueling events and operations, their instant transmission to the cloud servers for logging and recording in the data banks for further analysis so as to provide real-time data on the relevant dashboards as well as generate various reports on schedule and on-demand and produce alerts and notifications to the directly concerned parties.

Just as computerized accounting software revolutionized manual accounting back in the ’70s, this is considered our day’s revolution in Automated Fuel Management and Automated Fluid Accounting.

In this manner, operator errors and mischiefs are eliminated and by placing strict control measures like trip allowance and periodic fuel quota and calculating fuel consumption, at the end of the day all the figures must add up and the received quantities should reconcile to the dispensed amounts. With REST API provided, all data can easily be integrated with any ERP system, too.

The system is basically determined to increase the efficiency of the entire operation by providing real-time accurate information to the fuel management team and ensuring ample availability of fuel in the stationary storage tanks and mobile tankers, no abnormality is permitted without full scrutiny. Thereby theft, leakage, over-consumption, and wastage are quickly addressable.

This all translates directly into higher income by increased efficiency and productivity and lower costs by utilizing fewer human and machine resources and preventing wastage and loss.

Generating fuel bills and customer invoices are highly simplified backed with solid proof of a transaction with its timestamp and all other details.

Access can be granted to clients to log onto the system and generate the delivery notes of their fleet fueling to approve and process suppliers’ invoices.

Just as well, internally within companies with own fueling stations, each fueling transaction can be related to an expense center like a division or a project for project cost calculations.

The system can show current and past fuel levels in stationary vertical and horizontal storage tanks and mobile tanks selectively or accumulatively as well as show current and past received and dispensed quantities in and out of all authorized tanks.

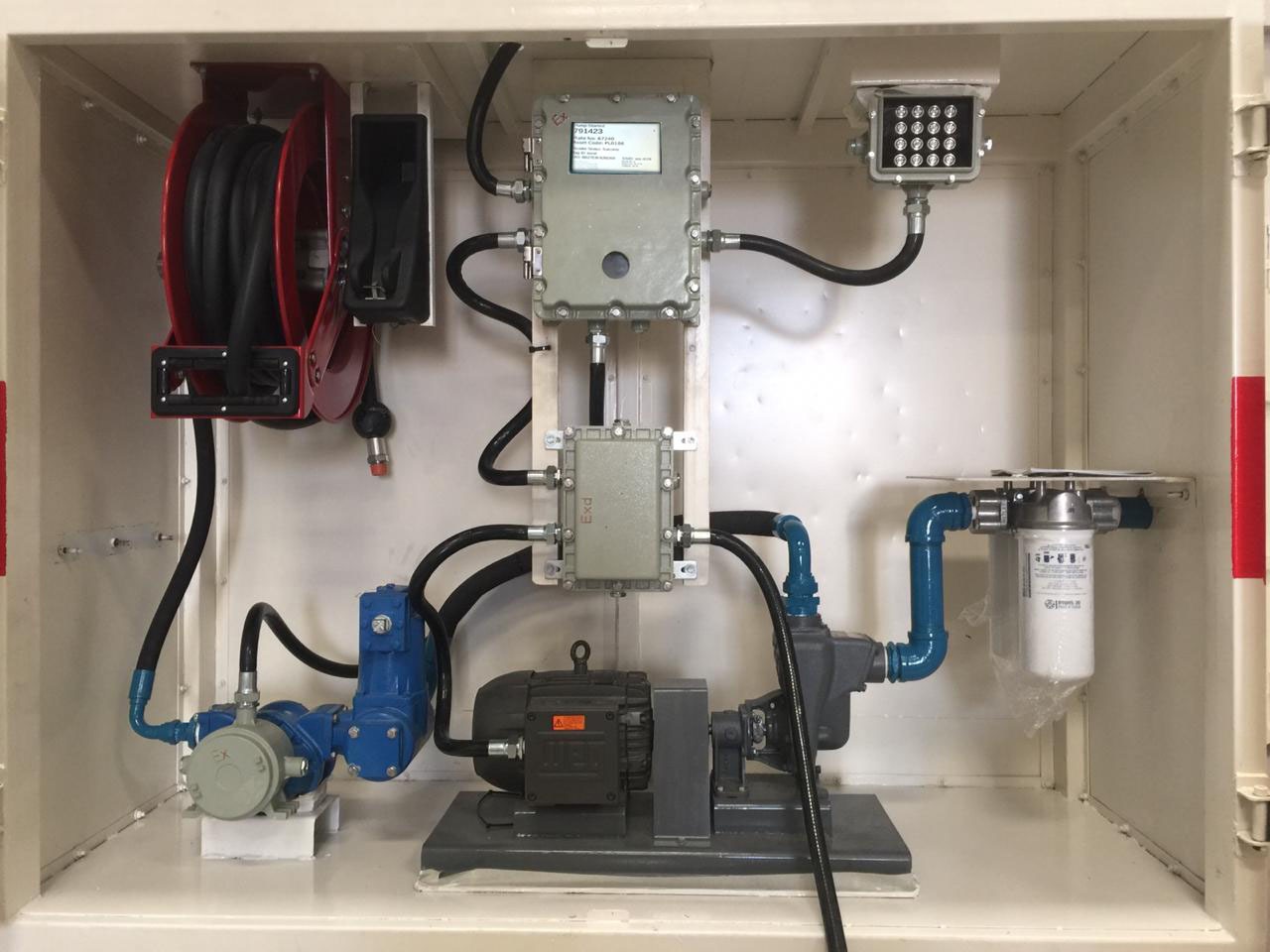

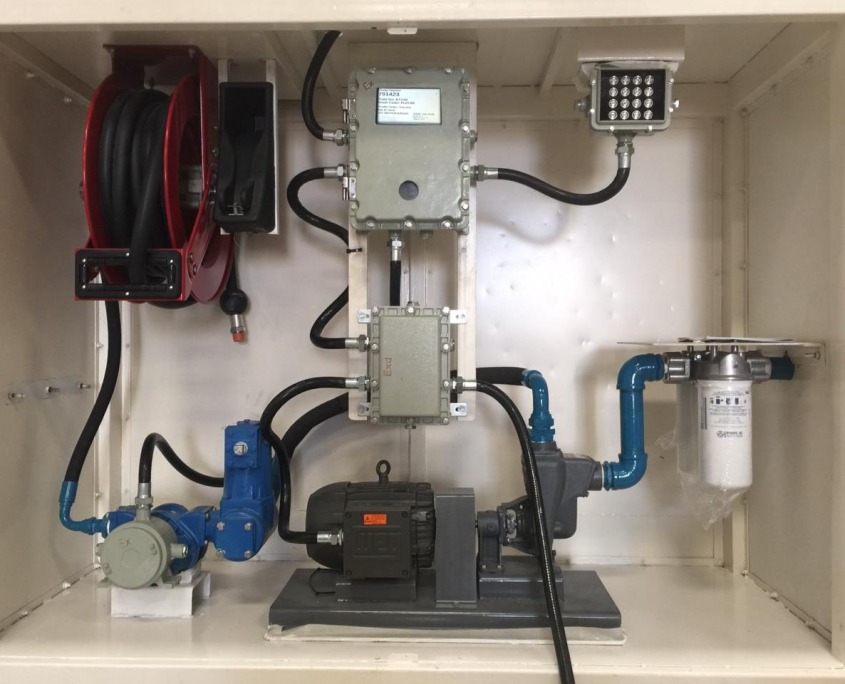

On average, the initial investment necessary to implement the Gatex Fuel-Eye is typically between 1 and 3 percent of the company’s annual fuel bill payable once. The cool thing is that the existing dispensers, nozzles, pumps, meters, and power supplies stay intact. The Fuel-Eye hardware work in conjunction with most existing hardware with the addition of a digital display to show the messages and instructions as well as the dispensed quantities.

The system is estimated to save companies up to 17% on their annual fuel spend so it would be safe to say the return of investment is well within the first year.